Technological challenges

The reconstruction of the Frauenkirche was a technical masterpiece. From an enormous mountain of rubble, the building was to be reconstructed using, on the one hand, historical building fabric and the incorporation of original historical plans, and on the other hand, using modern technology and up-to-date knowledge of structural engineering. A challenge on many levels.

To begin with, building plans had to be drawn up as a basis for a true to original rebuilding of the Frauenkirche. The aim was to rediscover the church's geometry that was lost with its destruction, to transfer this into building plans and to improve the bearing structure where necessary. Historical plans and floor plans as well as documentation of the reconstruction measures in the 19th and 20th centuries served as sources. In 1993, the ruins were photogrammetrically recorded in order to reconstruct the spatial position or three-dimensional form of the Frauenkirche by means of the photographs. The computer-aided creation of the three-dimensional initial model, which was intended to improve the supporting structure at a given location and correct earlier deficiencies, was a challenge, especially due to the Baroque architectural style with its many curved surfaces. The expertise and creative activity of the architects and engineers was particularly in demand for the conception and calculation of stability and stability.

The Frauenkirche is made of sandstone. This natural building material has high strength, is visually appealing and easy to work with. Moreover, it was and is available regionally: Both the sandstone for Bähr's and the rebuilt Frauenkirche came from the Posta quarries in the Elbe Sandstone Mountains near Dresden. What in the 18th century still had to be quarried with great physical effort and then transported by ship down the Elbe to Dresden, could be technically supported during reconstruction. Blocks of stone were blasted off in a controlled manner or cut using a high-pressure water jet. In workshops, stonemasons carried out adjustment and finishing work. The finished blocks were transported to the construction site exclusively by land.

During reconstruction, the structural engeneering plans specified exactly how far the stones had to be interlocked, how thick the joints had to be, and what quality of mortar was required. This was particularly demanding for the piers, the dome and the interlocking of old and new stones. For the Frauenkirche, a special grout for thin joints was developed to meet the strict specifications (6 mm). Special attention was paid to the eight interior piers. They had already been of decisive importance in the original load-bearing concept, but the force flows were in part different from those intended by the Baroque architect Bähr. Therefore, elaborate calculations were made during the reconstruction to correct the load flow. In addition, only the highest-quality sandstone blocks were moved, and their cutting was not allowed to exceed tolerances of 1.5 mm (!). The contact areas of the piers were widened and fewer individual blocks were used per layer in order to reduce the number of joints. Finally, great care was taken to maintain the joint thickness and the mortar quality, so that in total the load-bearing capacity of the pier masonry was doubled.

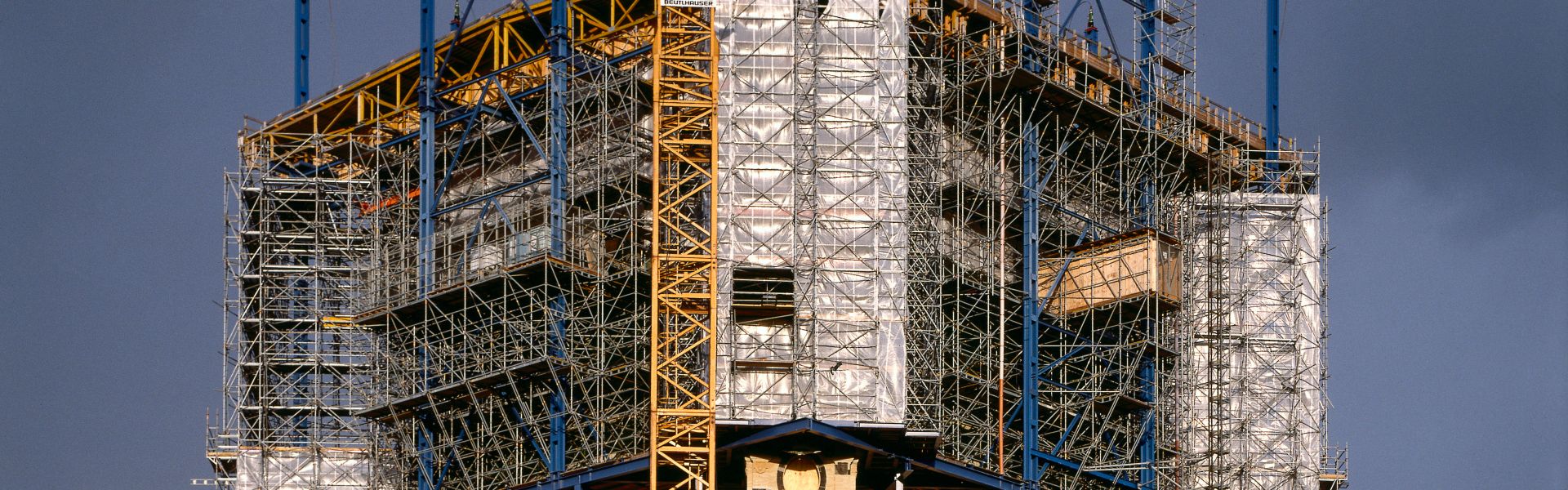

A large number of scaffolds were needed for the reconstruction. The number of scaffold poles was enormous: the wooden decks alone for the scaffolds for the outer structure up to the start of the dome approach filled 12 semitrailer trucks! Again and again, it was necessary to develop special solutions - whether the scaffolds were to provide access to higher sections of the building or to temporarily support parts of the building. For many arches and vaults, elaborate formwork had to be constructed. This was done according to traditional craft rules. The forms to be created were often complex due to multiple curvatures in some cases. The formwork for the arches between the interior piers and for the interior dome and the main dome were particularly demanding.

A special feature of the Frauenkirche construction site was the height-adjustable weather protection roof. For a construction site of this size, there was no model for this. But because work had to be guaranteed regardless of the weather, a solution had to be found. In 1996, a construction was created that could be raised hydraulically. It was raised a total of five times and rebuilt twice to adapt it to the progress of construction. By the time of the first reconstruction between January and March 2002, after three lifts up to 44 m, the nave, the inner dome, the beginning of the tambour cylinder, the dome approach and the lower part of the stair towers had been created. For the construction of the dome, a new supporting structure was erected on the dome approach, from which the roof was lifted to a height of 57m. The fourth hydraulic lift took place at the end of 2002, before another reconstruction was carried out to complete the lantern neck and lantern. In July 2003, the roof, which now only covers a small part of the dome, was erected at a height of 76 m before reaching its highest position of 83 m in November of the same year.